Burners Shut Down, Cycle, and Inducer Motor Not Running

Who specified those isolators anyway?

Failure Background

While visiting (the) home (in which i grew up) over the December holidays in 1994, i noticed that the room in which i was sleeping seemed awfully cold, and the central attic furnace, a Day & Night-badged 376B (specifically, a 376BAW036075), was running only briefly and not outputting a lot of hot air. This was Especially Not Good as i had a cold at the time! As was typical, my parents had not noticed, though it could possibly have been a recent or new failure. Pulling the cover off (my first time with this furnace) did not immediately reveal a problem to me (though it would have to an HVAC pro).

Troubleshooting and Repair

Pulled out the instructions, and studied the Sequence of Operation, parts layout, and schematic. It became readily clear what a pro would have noticed right away: the Inducer Motor was not running when it should have been. In fact, it was not running at all, ever, during the cycle! (This was my first introduction to horizontal-draft furnaces and inducer blowers, hence my not immediately realizing the problem.)

Soon found that the motor was not getting any voltage. Found one pair of the Inducer Motor Relay contacts nicely burned. Spent some quality time cleaning them with my relay burnishing tool and what was then Cramolin® R-5 contact cleaner. Found some burned up traces or parts on one or both of the main control board and/or the Inducer Control Board (hard to remember as i type this up 14 years after the event). Whatever the case, there was no power to the motor when i got into the job, and there soon was once i fixed the various burnt items in the circuit path.

This naturally led to the question: Why did the circuit torching occur? My attention naturally turned to the motor, which i found to be stiff and not wanting to turn. Out it came (an adventure in and of itself for a first-timer). The bearings had seized, especially the one nearest the blower, i suppose from the heat/flames and lack of air circulation with that blower unable to run likely drying out the lubricant that much faster. Vague memories of lots of powdery residue around the blower wheel (“blades”).

Disassembled the motor, removed the NSK 608Z bearings. Worked those puppies over quite well with cleaning and soaking/spraying with lubricants, including Tri-Flo® Teflon®-based oil, for several hours. At the conclusion of this process with fresh lubricant well worked into the bearings, they were again fairly smooth (the rear bearing, away from the heat, felt like new). During the soaking, i cleaned the powdery residue and whatnot off the blower wheel assembly and out of the housing which encloses it.

This re-lubrication, done in December 1994, has lasted through December 2008, 14 years of solid service from formerly seized bearings. The furnace was installed in December 1987, so the original life was only 7 years… half that of the re-lubed bearings. The bearings were still vastly more free and smooth than in 1994, yet were beginning to squeak, so i re-lubed them again following the same process. Hopefully in the upcoming weeks and months i will finally be able to find some solid replacements and actually change them next time they need attention.

But Wait, There’s More…

Upon reassembling and reinstalling the motor and then testing the furnace, the reason for the bearing seizure and motor stall and burned traces became clear: the motor could not turn freely! OK… why was this?

Careful inspection revealed that the three motor mount grommets had gotten all melty and saggy, dropping the motor out of its intended position. Manually holding the motor where it would be if the grommets were in their original condition (in the center of their mounting axis), the inducer blower spun freely and much more quietly (though never actually quiet), with no scraping nor metal banging sounds as when it could (barely) turn before. I was able to make a temporary fix by carefully selecting and rotating the melted grommets to get the blower wheel free and clear of its housing.

Fortunately, i was able to read the name of the OEM (Lord Mechanical Products, now Lord Corporation) and the OEM part number (J-2927-4-1) off one of the grommets. Having worked with this most excellent company earlier in 2004 for another project, i had access to their literature. It turns out that these rubber motor grommets were not speced to hold the weight of the motor assembly (4 lbs. by my measurement) in a vertical orientation (furnace in its horizontal orientation). Checked with the good folks at Lord: nothing off the shelf could properly hold that weight, though a different part (J-2927-4-2… same part with firmer rubber composition) could do better, longer before it too would fail. Lord graciously supplied several 3 piece sets of both the -1 and -2 grommets.

As it turns out, i was able to keep rotating the original melty grommets every few years when i was visiting and would hear the inducer blower making too much noise, until October 2002. At that time, i put on a set of the stiffer -2 grommets. Those are holding up decently, yet still do sag and do need regular rotation every few years. Unlike car tires, this rotation does not require “switching wheels”, just angular rotation so that what was the sag to the bottom is now up at the top.

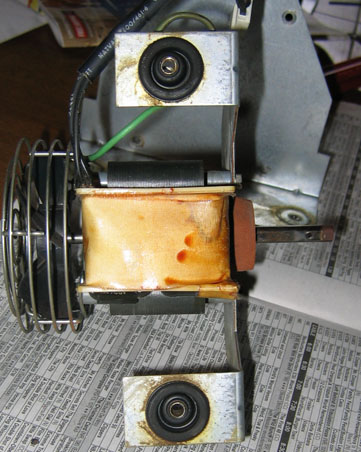

The October 2002 J-2927-4-2 set, as they looked in late December 2008

The mystery is why the BDP Company allowed this design error into production (engineering error? marketing cost-cutting override?). There were alternative grommets from Lord, and probably other OEMs, of a different design which could have been used and could have held that weight in either orientation this design would see.

Executive Summary

If the following steps are taken, this design defect can be rendered a non-issue:- The inducer motor grommets cannot properly hold the inducer motor long-term and will fail (at least for the 376B horizontal furnaces).

- If not too badly melted or deformed, the grommets may be spun (rotated) in place such that the “bottom” sag is now at the top, to prolong their life and avoid more catastrophic failure.

- If the inducer blower wheel is unable to turn freely, the bearings will likely seize and/or the relay contacts and/or circuit traces feeding the motor will burn up due to the overcurrent of the stalled inducer motor.

- The main burners will still light (and the main furnace blower will still run) if the inducer motor is stalled, yet the burners will not stay lit long. Thus the furnace will put out little heat and may run frequently and/or a long time.

- The grommets should always be checked with any furnace servicing, and dealt with as appropriate.

- The inducer motor bearings should be checked occasionally, especially if the motor is unable to spin very freely, or if there has been any overcurrent damage.

- If there has been any inducer motor stalling or excessive friction for any reason, inspect and repair or replace the inducer motor relay (or the whole board) and the circuit traces of the main control board.