Thermal Block (Boiler) Replacement

Paul’s 800ESXL Experience

Site correspondent Paul shares with us his experiences changing the thermal block in his Breville 800ESXL. Photos kindly provided by him.

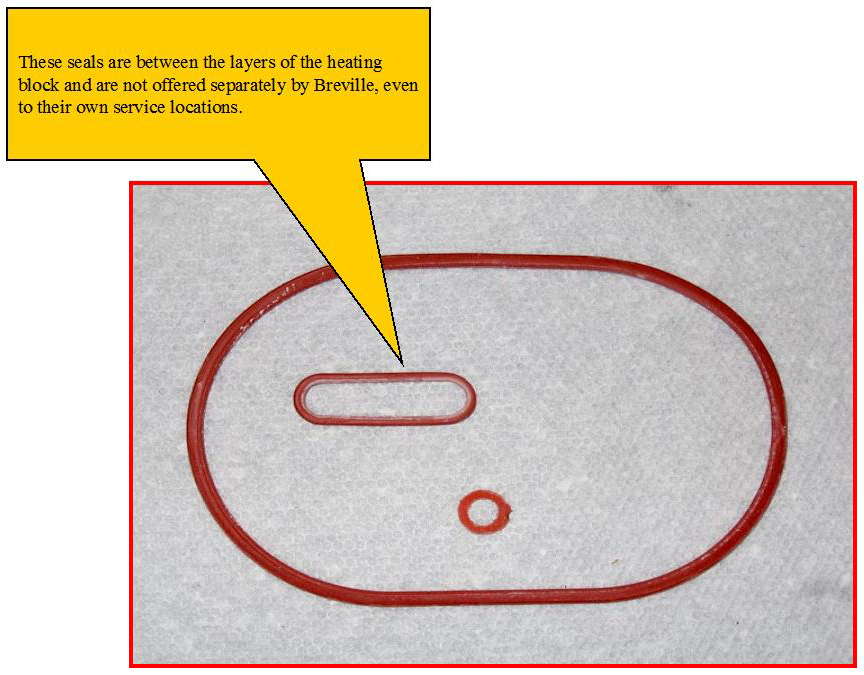

I also spent quite some time trying to get replacement seals for the boiler - not possible[1].

Ordering a complete replacement boiler is a slow process - they don’t seem to be stocked by anyone and it was a 6-week process for the vendor to get it from Breville and send it on to me.

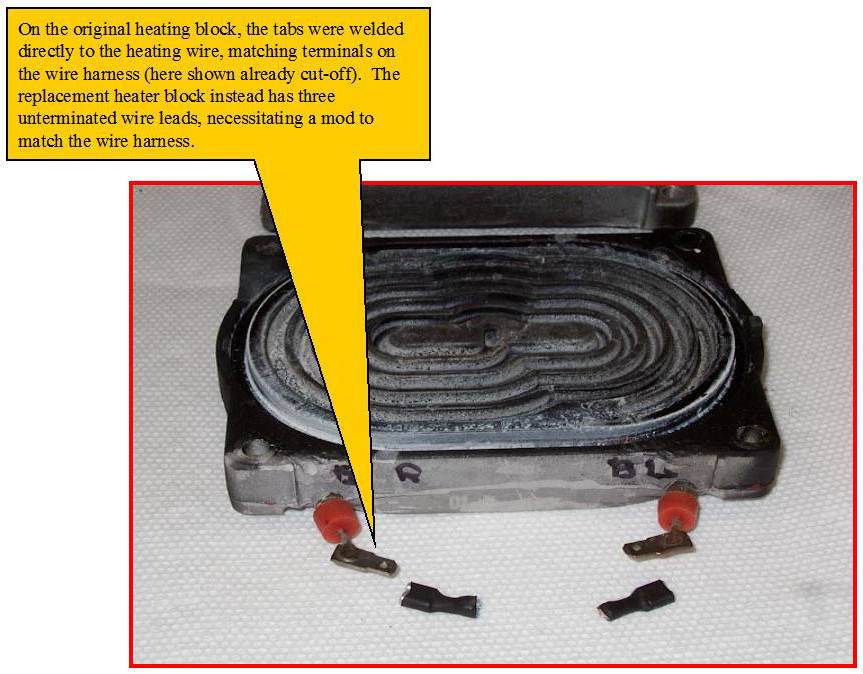

The design of the boiler has changed slightly. Whereas the original had electrical connection “tabs” welded directly to the ends of the heater element, the replacement has dangling wires. These are about 2" long and unterminated. Of all things, there are two blue ones and one red-brown. It seems that the boiler may be optimized for a different design now. The original disconnects on the heater are a funny sort - narrow but made of thicker than usual metal stock. I have the narrower spades but they don’t fit tightly into the terminal on the wire harness - they just flop around.

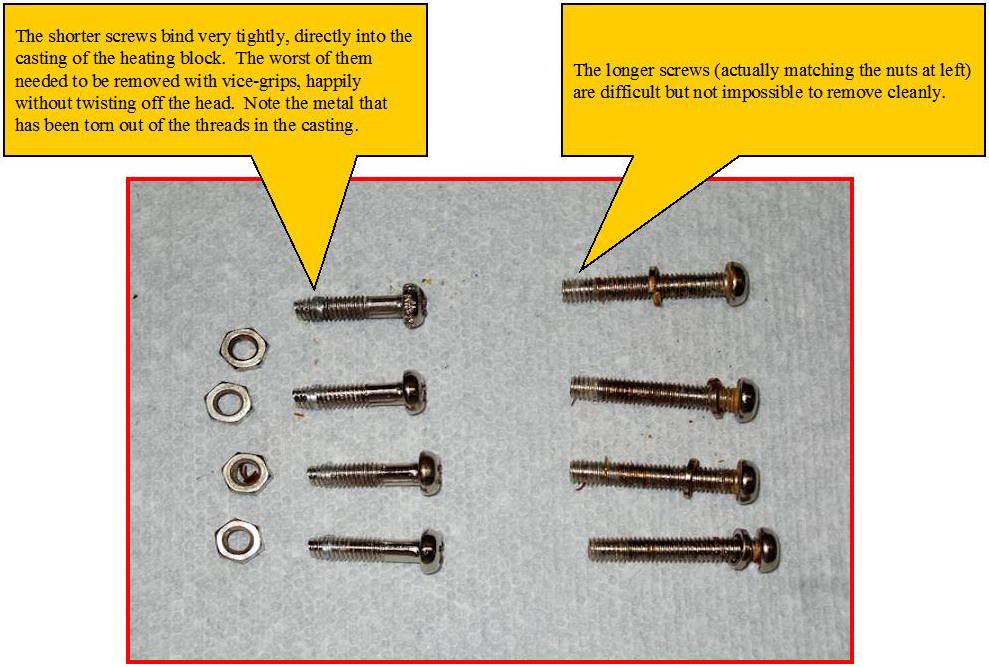

It seems that there is no end of little sniggles. The hole for the ground screw on the heater block was not tapped properly so the screw broke before getting tight - really poor quality screw, I have to say. OK, there is another spot nearby where it can be attached and there is a second ground wire on the heater block too. The two thermostats do fit on the replacement heater block but it’s not possible to tighten them down all that way. The screws are tight but the thermostats will still turn quite easily under the metal “hold down” rings. A bunch of heat sink paste should couple them well to the block - let’s see how it works long term.

It all went back together in the end but requires some “in the field modification” to make it work.

Cary’s 800ES New-Into-Old Retrofit Experience

Site correspondent Cary D. seeks advice regarding mating new thermoblock pieces into an older 800ES:

As your web pages noted, some of the original early model parts are no longer available. I've managed to get a list of the current parts and in my case I need to buy the whole new ThermoBlock assembly. Problem is the new version of this has a different connection to the water valve assembly that sits at the end of the pump.

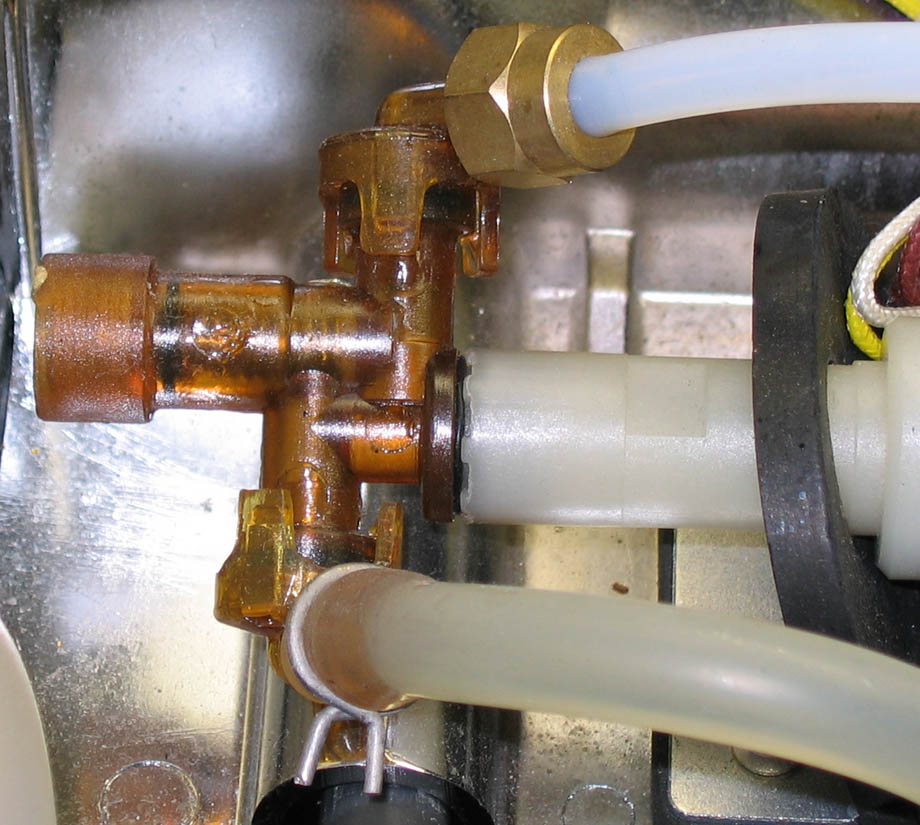

Mine is like the picture you have on your Mechanical/Water/Hydraulic Issues web page:

That is, there is a nut that tightens the hose from the water valve assembly that leads to the thermoblock.

The new replacement/updated versions of the 800ES have replaced this type of hose/nut attachment with a hose that has a small brass collar on it and a small metal pipe inside of it:

These obviously don't have a nut to tighten back onto the water valve assembly.

I'm wondering if anyone knows if there is a part or adapter that allows this new kind of hose attachment to be attached to the water valve assembly?

The reason I ask is that it appears the water valve assembly is still the same part number and appears to still be available. If there's not an adapter or something, my only other thought was that silicone tube that is on the outside of the hose is slipped over the same point on the water valve assembly and attached with a zip tie.

Would like to know if anyone else has done this kind of repair, ie. put a new thermoblock assembly with this new hose attachment into an early model 800ES.

Thanks.

Anybody have any suggestions for Cary? Let me know and i’ll pass them along (and if they seem to be of general interest, post them here).

[1] It may not be possible to get official seals from Breville any longer, though several enterprising coffee lovers have kept their Breville model 800s going via finding alternate sources for the gaskets/seals.

Return to the main Mechanical/Water/Hydraulic Issues - Breville 800ESXL Repair article