Dynamax CTR100 Tech Tips

By Sonic Purity, former KALX volunteer Staff EngineerThese tips date back to the end of the 1980s, but somehow never were published (at least not through me) until now.

Guess what? The entire CTR100 Series Preliminary Technical Manual from 1984 is now online, right here!

If you would like your own local copy (in case this site goes down in the future, or whatever), contact me to arrange for receiving a roughly 10 MB standard Zip archive file with all the same material in the same HTML + CSS format as here live on this site.

Stop That Motor!

Even though i can’t find it now, somewhere in the sales literature or manual is mention of automatic motor shutoff upon cart removal. When one turns to the setup pages, there is no mention of this feature, however. Careful inspection of the schematic and some judicious experimentation provided the answer. Pull out yer Servo Board schematic, and let’s go for a ride….

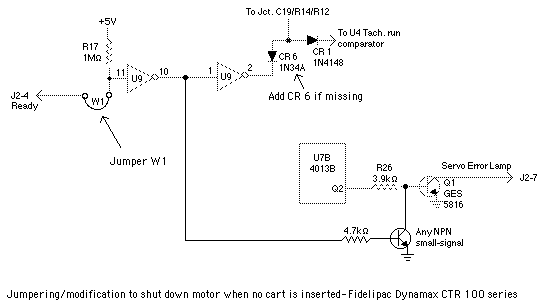

Notice diodes CR1 & CR6. These clamp the motor drive reference signal at C19 et al. As noted in Fidelipac’s circuit description, CR1 limits motor drive amp. current upon loss of tach. (detected by the CR2/3/U4 et al. comparator). Note that CR6 will do the same thing (but more of it, being germanium, with lower forward bias drop) whenever the Ready line is low (i.e., no cart inserted), if jumper W1 is in place. Some servo p.c.b.s may lack CR6. Any germanium signal diode should work (1N34A specified).

That’s all that’s necessary to switch the motor, but now we find why Fidelipac didn’t mention the option: the Servo Error light stays lit whenever the motor is at a standstill. This may be easily cured by pulling down Servo Error Lamp driver Q1’s base only when no cart is in place. The simple addition of one NPN small-signal transistor allows this to be accomplished by the same circuitry yanking on CR6 (namely U9 section E, 4069 pin 10). Now, no lights prematurely burning out, nor alarmed/confused operators.

In summary, install jumper W1 (and CR6, if absent), and add any small-signal NPN transistor as shown, and enjoy less noise, heat, and longer motor life.

Many years ago, Fred Buehler at Fidelipac was brimming with useful Dynamax CTR100 tips, including this quick solution for…

Insensitive Cartscan Sensors

Early production CTR100s sometimes suffer from erratic/failed Cartscan sensing in one or more modes. Inspect R41-44 on the Play Amp P.C.B. If these are 10kΩ, change them to 330kΩ for increased sensitivity.