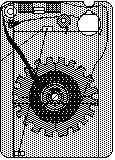

Fidelipac 300 (gray)

We might as well start by dissecting the original cart in agonizing detail, as that will lessen the time spent with its irreverent offspring later.

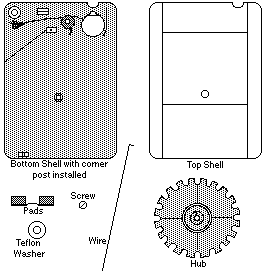

The original cart, the Fidelipac 300 (often called Fidopac by cart caretakers), adds a gear-toothed tape hub, a polysomething corner guide post, straight mylar/spongefoam pressure pads, teflon® washer, guide wire, and case screw to the obligatory shell and tape pack.

Note that the illustration fails to note that the white corner guide post is removable, with difficulty. Normally there is no reason to do so.

We got most of ours from KYA around 1980, easily octupling the number of carts we had. They continue to trickle in from all sources.

The pads are essential for proper operation, and are the most frequent source of failure in Fidopacs. Factory glue is often tough to remove, requiring patience, know-how, and a gentle touch. White glue works well for new pads only if it is deposited in the holder crack.

The teflon washer is nearly essential for smooth, quiet operation, but may be omitted in an emergency. The guide wire is desirable, but not essential, especially on carts of less than 70 sec.

The bottom shell consists of a brass hub center spindle, left corner hole for the guide post, pad holder, wire end holders, and brake mechanism. You will encounter many types of lubrication (or lack thereof) on gray Fidelipacs. It’s best to leave well enough alone, unless the cart sticks or squeaks, in which case remove the existing lube completely with the solvent of your choice, and try again. If it’s still bad or is now worse, re-lube with a grease-type lubricant (which should be available in the Cart Caretaker Kit). If one or both wire end holders is/are broken, they must be repaired, the wire must be removed, or the bottom shell must be stripped and tossed. Broken brake mechanisms are rare, but must be removed if encountered. Any other damage or breakage on the bottom shell demands disposal.

The top shell seldom has problems, short of being completely destroyed, with the exception of the center screw hole. The hard plastic is easily cracked by overzealous cart caretakers, as well as fumble-fingered programmers, etc., rendering the hole too big for the screw. Throw the top away, or waste a lot of tape to tape the seams together. The top shell removes straight up with no encumbrance, or use the label on the front as a hinge if you wish to preserve it.

The reel hub only causes trouble when the center tapered section separates from the main body. For some reason, these don’t glue back together well. Seeing as these carts are so cheap and pathetic in the late ’80’s -early ’90’s, chuck it. You will note the use of shiny black rods bearing an uncanny resemblance to pencil leads imbedded at 90°angles on some hubs. These are pencil leads. Originally intended to lubricate the edges of the tape for smooth sailing, they were found to be unnecessary. Ignore them. If they fall out, toss them, or take them home for your Scripto®s.